*Fixing Electrical Problems in Coleman Powermate Generators*

All of Coleman's portable Powermate line of generators use brushes to create an electrical connection the the rotor in the genset. This is a fine design, but anyone relying on a Powermate generator for emergency power needs to realize that the brushes are disposable components, with a usable life of 200 hours of running time. Furthermore, once one of the brushes is worn out, the generator will stop producing electricity, without any other outward signs of anything being wrong.

I've worked on some Powermates that are used by ranchers to pump water from wells for livestock, and in fairly dusty conditions they will go through a set of brushes in two weeks or less. If you ever have to make heavy use of a Powermate in an emergency, this is a problem you will encounter.

Fortunately, replacing worn-out brushes is a very simple operation that requires no special tools, and new brushes cost less than $5 per set.

Step One - Diagnosis

If your Powermate stops producing a usable amount of electricity while the engine is still functioning - specifically, if the output drops to 2-5 volts - the chances are very good that worn brushes are the culprit. There are other possible causes, but brushes are far and away the most common.

Step Two - Removal

On the rear cover of the genset you will find a small rectangular panel. Use a screwdriver (or something similar) in the bottom notch of the panel to pop it out.

Inside you will see two metal tabs secured in place with small screws and a large bolt. The tabs are the ends of the brushes, and the bolt is holding the rotor in place.

Remove the screw from one of the brushes and pull it out of the genset about a quarter inch. To the left of the screw hole it will be held in place by an electrical clip.

Use a pair of small pliers (I prefer small lockable tongs) to hold the female end of the clip in place, and pull the male end free. The pliers are there both to prevent pulling the clip too far out and also to prevent the clip from pulling back inside the genset after the brush is removed.

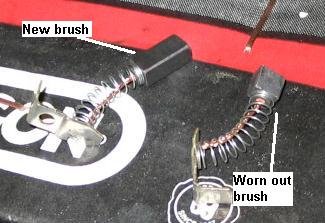

Step Three - Inspection

A totally worn out brush will have a quarter inch or so of contact remaining. It is very rare for a generator with a brush that worn to be producing power. If the brush is less than 3/8ths of an inch long, it should be replaced.

Be aware that one brush will usually wear much faster than the other. Even when one is rendered unusable, the other will often be in decent shape. In this case, you need only replace the one brush - they don't need to be done in pairs.

Step Four - Reassembly

Installation of new brushes is as simple as removing the old ones. Slide the brush contact into its guide hole, hold the electrical clip in place with your pliers, and push the brush into it. Then replace the screw.

Now test the generator. If you are replacing a brush before it has completely worn out, you should get power as normal at this point. If the brush was worn enough to stop working, you may well have to repolarize the generator before you will get power.

Step Five - Repolarizing

This step may sound daunting, but it is actually a legitimate maintenance procedure, also known as "flashing" the generator. Sometimes a genset will lose its polarity when a brush wear out (or if the generator is heavily overloaded). To fix it, you will need a 12-volt car battery (jumper boxes work well) and a set of cables for it.

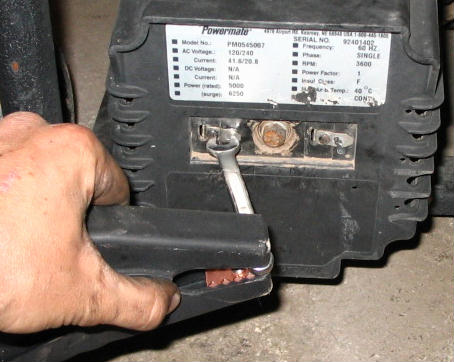

To repolarize the genset, remove the small place covering the brushes. Then start the generator.

Then you will need to hold the negative lead from the battery in contact with the exposed portion of the left brush, and then tap the positive contact against the right-hand brush. It will make a nice blue arc and a popping noise, and you should be able to hear the generator take on a bit of a load. Sometimes this must be done two or three repetitions for this to work (if three don't do it, you have bigger problems). Now use either a multimeter or appliance to test the generator's output. It should be back up to the standard voltage (Powermates usually produce about 130 volts at the outlets).

I realize how this sounds (I was pretty dubious when it was explained to me at first), but it does work, and is necessary.

You may see in the photo that my jumper leads are too large to use on the brushes, so I clamp a small wrench in each one and use those as contacts. It's a very redneck workaround, but it does work.

Addendum - Getting Spare Brushes

Your local engine shop should have no trouble getting brushes if they have an account with Coleman. Dealer cost per brush is $1.35, so expect to pay about $2 each. If your shop can't get them, call Coleman (there should be an 800 number on your generator) and they can direct you to a local source for parts.

Penwu

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2006 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.