*Operating and Hooking up a full size range to a 20lb Propane Tank*

My wife and I have doing a great job of filling up the pantry with all sorts of canned foods, rice, flour, and everything else that we eat. Remember "Store what you eat, eat what you store." No matter where you look on the Rubicon you will see that phrase over and over again. Well, we certainly have stored many items, most of which taste better cooked, and some have to be cooked. One of the holes in my preps has been an alternative way to cook, bake, and boil water; pretty hard to run an electric range off of a generator or solar power, so after discussing this with the wife we decided on a full sized propane range.

So, off to Craig's list; after searching for a few weeks we finally had a hit, he was asking $150.00, and it looked in very good condition. I don't know about you but I never offer the asking price, so I fired off an email, " will you take a $100.00" a few hours later I got a reply, " I guess so". I was there that evening picking it up before he received another offer. The stove looked even better in person.

I couldn't wait to go out the next day to get a regulator to hook it up, this was going to be a ten minute job; ever do a ten minute job at home, how long did it really take? Yup, that's what I thought. I went to a local welding and gas supply house and asked for a propane regulator. All he had was an industrial adjustable with a tee handle in the top, for $40.00, buy once cry once, so I paid the 40.00. There were no arrows indicating which way to turn the handle to increase or decrease the pressure so I asked the sales rep and he said "Just turn the handle clockwise and it will increase the pressure”. My 2nd mistake was leaving the store with no operating manual, first one was thinking this was going to be a ten minute job.

I had most of the brass fittings and 3/8 pipe, the only thing lacking was the 3/4" adapter that went into the hose on the stove. So off to Lowes I went, the largest one they had on the shelf was a 5/8”, I spent the next 15 minutes looking through all of the bins with no luck, then it hit me; I remembered that my house used to have a gas dryer, and that I was pretty sure that there was still an adapter on the old gas line; another 15 minutes to remove and cap the line; but I had the adapter.

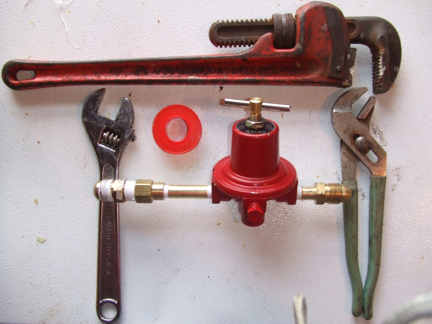

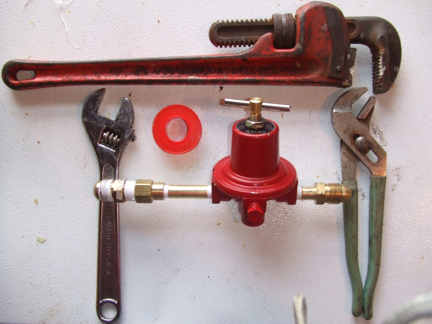

Here is a picture of the regulator, fittings and tools that I used to put everything together:

Here is another picture of the regulator attached to the tank, you must be careful because the adapter on the high pressure side (right side in the lower picture) screws in turning to the left, you don't want to strip the brass.

This is the final connection, to the stove

This is the tag that shows that the stove has been converted to propane, the date and technician who performed the conversion; it is an absolute must that you be 100% certain that the stove you are using is set up for propane.

Okay, now the big moment has come. I open the propane tank and go to the front of the stove, turning the knob to the starting position I hear the air escape, the electronic igniter clicking away, ( you can still use a match to light the stove without electricity) and then nothing, the gas completely stops, no blast off, no ignition, no nothing. My heart sinks, then comes my favorite saying " Awe Man! Now what!" I check the connections, turn the regulator down even more and still nothing. I pulled the regulator and slowly cranked open the propane valve and still nothing. So what do I do next?

What else, I go and post on the RUBICON looking for help; within an hour of posting I received several responses back, offering great suggestions from ColoFireMedic, Spitfire, Pyrotech, Techsar, and Warthawg; one of the suggestions was to turn the propane bottle open slowly as not to trip the safety valve in the regulator, the other problem was the sales rep told me to turn the handle clockwise turning to increase the pressure. "Wrong" turning the handle in actually reduces the flow of gas, so in effect I was shutting the gas off. Had I obtained the paperwork on the regulator I could have figured that out. I backed the regulator completely out, and slowly opened the propane tank, went to the front of the stove tuned the knob to the starting position, I could hear the air being displaced in the line, and then, there it was, a pretty blue flame!

Now for some FNV, I wanted to know if I there would be enough gas pressure and flow to run all four burners and the oven at the same time.

The picture says it all, I had all four burners running, and the oven warming up to 350 degrees, no problem. So there it is folks, you can operate a propane stove on a 20lb. tank. My next task is going to be to figure out how much propane it takes to run each individual burner, and the oven, so I can calculate how long I can operate on one 20lb tank of gas; (will I get 24 hours on a small burner or 15 on a large?) I am going to see if there is a manual on line for the stove, hopefully it will have the burn rate so I can figure it out mathematically instead of burning up the propane.

One of the things that I took for granted is that I thought I knew all there was to know about propane tanks and regulators, Wrong again, what I learned is never take anything for granted, a lot of my knowledge was just passed down to me; from now on I'll research my project first, make sure I have all of the proper manuals, and ask other members on the Rubicon prior to me starting my project , for the most part, whatever your trying to do has already been done, all you have to do is ask.

I am attaching some great information and pictures on propane tanks, regulators, and OPD Valves.

Here is a cut view of a propane tank showing the OPD cylinder valve, ( Overfill Prevention Device) this device is required on all tanks from 4 to 40lbs. This device prevents a tank from overfilling. It acts like a toilet bowl float when it reaches a certain level the flow of gas stops entering the tank. The OPD valve will still let gas out of the bottle even if the bottle is inverted or on its side. The OPD valve will not let any propane out if it is not connected to anything; other than that the OPD does not ever restrict or stop the flow of gas.

This is looking into the end of the OPD, you can see the internal gasket and valve that needs to be depressed before any propane will be released from the tank.

Hose End Connection

The hose end connection on either a fill hose or appliance supply line is designed to work only with OPD equipped cylinders. For the OPD valve to operate with the hand wheel open, the hose end connection must be securely attached. The picture to the left shows a hose end connection. Notice the elevated brass fitting is surrounded by acme threads. When attached to a cylinder valve and tightened, the brass fitting will push the internal valve open and allow gas to flow out of the cylinder to the appliance, if the hand wheel is in the open position. This fitting must be in place for gas to flow out of the cylinder. Otherwise, turning the hand wheel will not produce the intended result.

One thing that I do is make sure that all of my tanks that I have in storage have caps on them, for some reason spiders like to make nests in there.

Here is a picture of various regulators:

The propane gas regulator is one of the most important parts of a propane gas system. The purpose of the regulator is to control the flow of gas and lower the pressure from the tank to the appliance(s) in the gas system. The regulator not only acts as a control regarding the flow and distribution of propane but also as a safety barrier between the high pressure of the tank and the end use appliance(s). Most will rightfully argue that the LP Gas regulator is the heart of any propane gas system.

Propane tank pressure can range from under 10 psig to over 200 psig. Residential applications will generally require 11 inches water column (amount of pressure required to push a column of water up 11 inches in a manometer, or about 6.3 ounces per square inch) and the regulator compensates for these pressure differences in the tank to supply a steady flow of required pressure to the household appliances. Not all applications are similar to that of residential use and will therefore utilize regulators for higher and lower pressures as required by the appliance(s). In summary, the purpose of a propane regulator is to "bottleneck" the propane down to a safe and usable pressure. An important point to note is that under normal operation, a propane regulator will make a "humming" noise. This is normal and should not be construed as a problem or regulator malfunction.

A great reference site that I used is: www.Propane101.com it has all the information that you need to help you understand propane and all of the equipment associated with it.

I now have an alternate way to cook and bake if needed; there is something to be said about quality of life, I don't know about you but I like the convenience of cooking on a full size stove. If needed, I also have a 500 gallon propane tank that I use to heat my metal shop, if I have to I could easily move the stove to the shop; 500 gallons for just cooking would last a long time.

Tinman

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2008 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.