Ever wonder about small scale wind turbines - everyone that has had the solar itch has thought about throwing up a turbine or two to supplement their solar production. So stop and ask yourself why not? We've had ours up for years now and although they are not as maintenance free as solar panels it is really nice to look out the kitchen window and know you can run the lights in your house from wind power...

We own:

- an Eagle 1000 watt

- 1 Air-X series 12 volt unit

- 3 Air-X 48 volt units

Up until this past fall we have had no problems whatsoever so I guess we had a few coming...

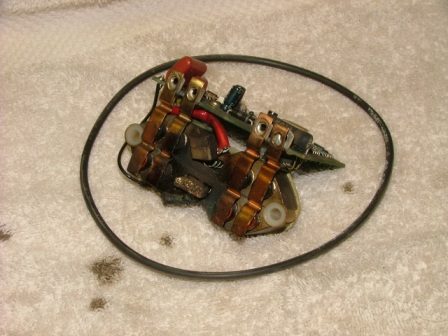

Our good fortune with the wind turbines was not going to last forever so when things do go south it pays to have spare parts and other needed gear to support routine maintenance. This past fall our AR 403 failed and we had to pull it down the yaw block had failed and the slip rings had misaligned themselves with the brushes resulting in a direct short of the downwind power bus. The stator fried itself as well as the regulator and the yaw block which contains the slip ring assembly.

Charred Stator Windings

Close Up: AR403 Yaw Block With Slip Ring Assembly

One small failure has the potential to create a cascade of other failures. The cost to repair these failures was near $340.00 So I decided to just buy another and use the failed one as spare parts carcass. We even used the power head (rotor) as part of my son's science fair project.

Note: Barbequed Electrical Components Really Stink

When the stator "cooked off" note the charred effect...

Considering that the AR series of turbines are a complete unit with voltage regulator and all electronics housed in an Aluminum casting sealed with o-rings it is a technological marvel in its own right. These little machines are great - we run a freezer tied to a large battery bank on one of these units - so nearly in nine months after the installation the temperature alarm in the freezer has not sounded off and dinner tonight came from that freezer.

A few weeks ago the LED on the base of one of our other units decided it was not going to light up. The AR series utilizes a POST similar to a PC when a battery is connected to the output. It blinks twice if the system is "A" okay and does several other things while running like letting you know when the battery voltage has reached the point of regulation. At the rear of the Aluminum case there is an Pot for adjusting the point of regulation which allows you to set up the unit on the bench before climbing the pole. Today I pulled the unit down and went through the diagnostics in the manual and the end result was that the internal regulator was bad. After a few phone calls to technical support and another bench test they came to the same conclusion as I did and provided an RMA number to ship the unit back to the factory. The out of box warranty is 3 years so life is good. There was slight admission that there have been a few units to leave the factory with minor issues. We also own an Eagle 1000 watt turbine that has been in place for quite some time and the wife has complained that she can see the hub wobble... so while up there today we decided to pull it down for inspection. The Eagle series of wind generators are based on large Tractor trailer sized alternator that are converted with permanent magnets so that they do not need an external voltage applied to generate power. These units are very robust at the core but the external packaging and gear added to turn it into a wind turbine is less than world class... unlike the Air-X units.

Getting Ready To Remove The Turbines

Eagle Before Removal

Mt Adams In The Distance - Life Is Good Here...

Preparing To Bench Test Output

Excessive Wear Where Undercut Meets Face Shoulder

Once we got the Eagle down we found that the hub could freely turn on the rotor shaft as the hub had friction machined a groove behind the undercut where the thread form bottoms out. This resulted in excessive clearance between hub and rotor shaft allowing the rotor to free wheel at startup. When a drill motor was used to turn the Eagle it performed exactly as the manual said it would. The tail on the turbine beam is made from .030" thick sheet metal which has cracked in several places near the attachment holes. My plan calls for refurbishing this unit and putting it back into service at my radio shack.

To sum up: Home use of wind turbines is really cool, can save you some money and does the right thing for the environment. Cost of individual units can vary from dealer to dealer so shop around and find the best price. For what little trouble we have had with the Air-X series - we highly rec. them to other folks looking for other means of producing power by an alternative method.

In a future article I will chronicle the effort to rebuild the hub and the tail section of the Eagle before it is put back into service.