*Building a Bug-Out Jeep Trailer: Part 1 - Planning*

First off, here are some of the goals I wanted my trailer to fulfill; hopefully most of them will be met before we’re finished.

· Same track width as the Jeep

· Same tire and wheel size for maximum flexibility

· Small and maneuverable

· Extremely durable

· Relatively inexpensive

During my research for this project I encountered several commercial options, however, they were all deemed too expensive. Although some of them are pretty impressive, I just wasn’t willing to shell out $10,000+ for something that I “knew” I could build.

Here are just a few of the trailers I used for “inspiration”.

http://www.off-roadinternational.com/trailers.html

http://www.safaritrailers.com/

Now that I had an idea of what I wanted to build, I further refined by requirements for key components.

Axle, wheel, and suspension requirements:

· 60 inches to match the jeep’s axle

· 5 x 4.5 bolt pattern, with 5 inches of backspacing to match the jeep (standard for a Jeep Wrangler Rubicon).

· 3000 lbs for strength

· Leaf spring suspension for simplicity, again at least 3000 lbs

· 31” tires

| Part Number | Description | Qty | Total Price | Source |

| KT3561HF | 60” track axle | 1 | $73.37 | Auto Safety House |

| 84 | Bearing Kit | 2 | $18.12 | Auto Safety House |

| 8-248-5 | 545-Hub | 2 | $43.22 | Auto Safety House |

| 093184 | 4-Leaf 1750# 25 ¼ leaf springs | 2 | $55.34 | Auto Safety House |

| XP10W0301 | 1000LB Swivel Jack | 1 | $53.08 | Auto Safety House |

| 222000500 | 2x2 hitch coupler | 1 | $16.54 | Auto Safety House |

| 60190301 | Hanger Kit | 2 | $17.64 | Auto Safety House |

| H74951 | LT245/75R16 Trail tires | 2 | $269.50 | Big O Tires |

| 92601 409 08 | CRAGAR 397 16X8 5X4.5 Wheels | 2 | $105.98 | Quadratec |

| Total: | $652.79 | |||

Frame requirements:

· No longer than 9 feet in length (so it will fit in my garage, and for maneuverability)

· Width defined by the axle length, plus additional space for tire clearance

· 2 x 3 x 0.120 rectangular steel chosen for strength

· Integral tongue for strength

This is the steel that I purchased to get started.

| Part Number | Description | Qty | Total Price | Source |

| Frame | 2x3x0.120 Rectangular Tubing | 40 ft | $162.00 | Jan's Iron Works |

| Box | 1 ½ x 1 ½ x 0.083 Square Tubing | 50 ft | $98.44 | Jan's Iron Works |

| Total: | $260.44 | |||

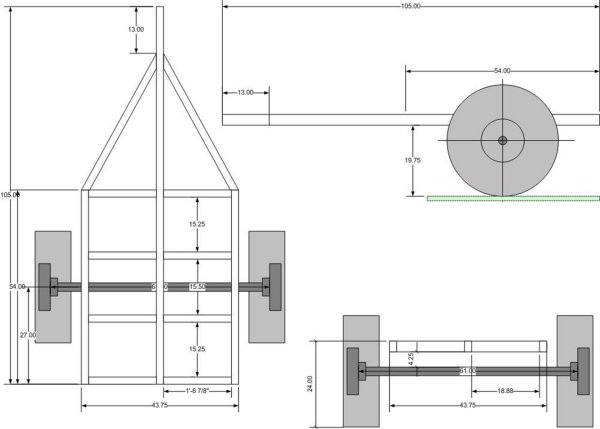

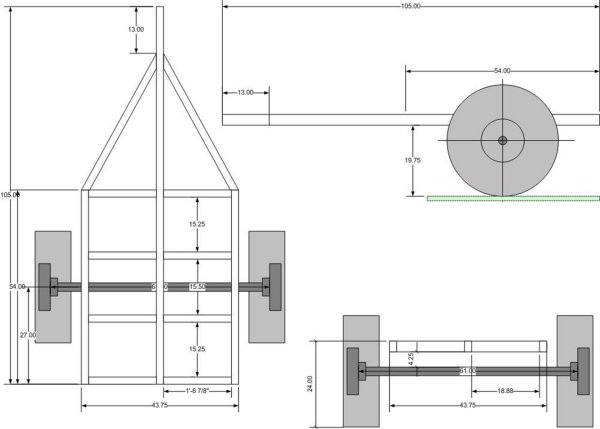

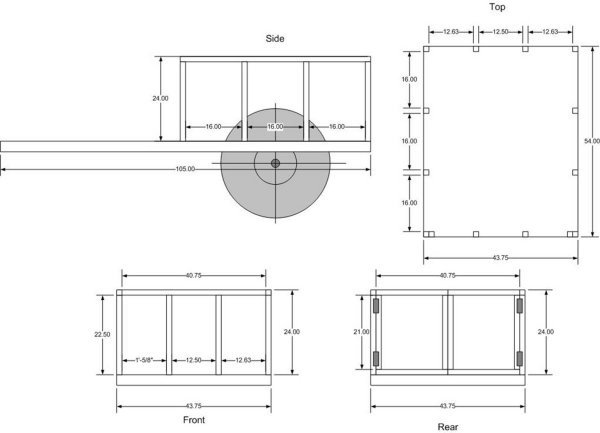

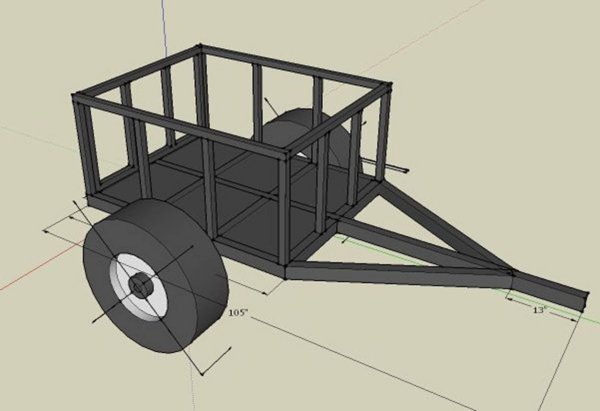

Now that I had all of my requirements nailed down and suppliers for all my materials identified, I set to work on some plans. I used a combination of Microsoft Visio and Google Sketchup for visualization. This is what the plans looked like when I started welding. One thing to note – at this time I had no idea what I was going to do for fenders, as you’ll see in a later article, I managed to come up with some beefy ones.

The Frame

The Box

Google Sketchup Rendering

In the next article we’ll fire up the welder and get started on the Frame.

Azgard

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2007 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.