*Testing Diesel Engine 2*

By: Woodbutcher

13 September 2009

Recently, I purchased a new-to-me truck. It is a 2001 Dodge Ram 2500 with a 5.9 Cummings diesel engine. During the initial look over and test drive of the truck, everything appeared to be ok. The truck started and ran fine, looked good, Carfax didn’t run up anything and neither did a dealer check on the VIN. The deal was closed with the seller and I brought the truck home.

Shortly thereafter, I noticed the truck didn’t have the power it should have. The truck seemed to run fine until I put a load on it. The load could be as small as 2,000 pounds of hay on a trailer or as large as a 7,000 pound camper. I thought maybe the fuel filter was clogged so I replaced it. This didn’t help. I did some inquiring with a local diesel mechanic, and he suggested I run a fuel pressure and flow test on the low fuel pressure system. He said these tests would rule out the lift pump and filter system. If the test showed I had low pressure and/or low fuel flow, I could find the problem and make the proper corrections. I gathered the items needed to run these tests and set out to find my problem.

Note 1: This procedure works on a 1998 through 2004 1/2 Dodge Cummings 5.9 liter ISB engine. I do not know if it will work on any other make or model of diesel engine.

Note 2: Diesel engines have an injector pump and a lift pump. The lift pump supplies fuel from the fuel tank to the injector pump. The lift pump is sometimes referred to as the supply pump, the primary pump, the secondary pump or the transfer pump. For the purposes of this article the lift pump will be referred to as “the lift pump”.

Note 3: The injector on this engine is a Bosch VP44 and will be referred to in this article as the injector pump or the VP44.

To test the fuel pressure you need a diesel fuel pressure test gauge and fitting. I borrowed one from a friend that is a diesel mechanic so I don’t know the exact make and model number of the gauge kit. His looked similar to the one pictured below. I believe you could make one with a gauge, a piece of tubing, and a fitting to connect to the Schrader valve.

You will connect the pressure gauge to the Schrader valve at the injector pump. A Schrader valve resembles the air valve on a tire. There is one located on the inlet of the filter housing and one on the inlet of the injector pump. Below is a picture of the one located on the injector pump. It is the one with the black cap.

Once you have the gauge connected to the Schrader valve, be sure the gauge and tubing are in a safe location, away from any moving parts on the engine. Start the engine and read the gauge. The minimum pressure for the injector pump, the VP44, on a 5.9 Cummings ISB engine needs to function properly is 5 psi. Preferably, you will have 8 to 12 psi at the injector pump. If not, you will need to test the pressure between the lift pump and the filter housing to be sure the filter is not clogged. Look for the Schrader valve between the lift pump and the filter housing. The factory OEM lift pump is mounted on the driver’s side of the engine block. Again, the minimum pressure you should see at this point is 5 psi, with 8 to 12 psi being preferred. If you do not have a minimum of 5 psi at this point, the lift pump is failing or failed.

To check the flow rate of the low pressure fuel system you will need a length of ¼” ID clear rubber or vinyl tubing approximately 4 feet long and a graduated container that will hold a minimum of 60 fluid ounces. I purchased the tubing at my local Lowe’s. The clean graduated container I picked up at the local Dollar Store for a dollar. It is a ½ gallon pitcher with fluid ounces marked on one side. You will also need a clean diesel fuel container of any size. I used a 5 gallon fuel can marked for diesel that I had on hand.

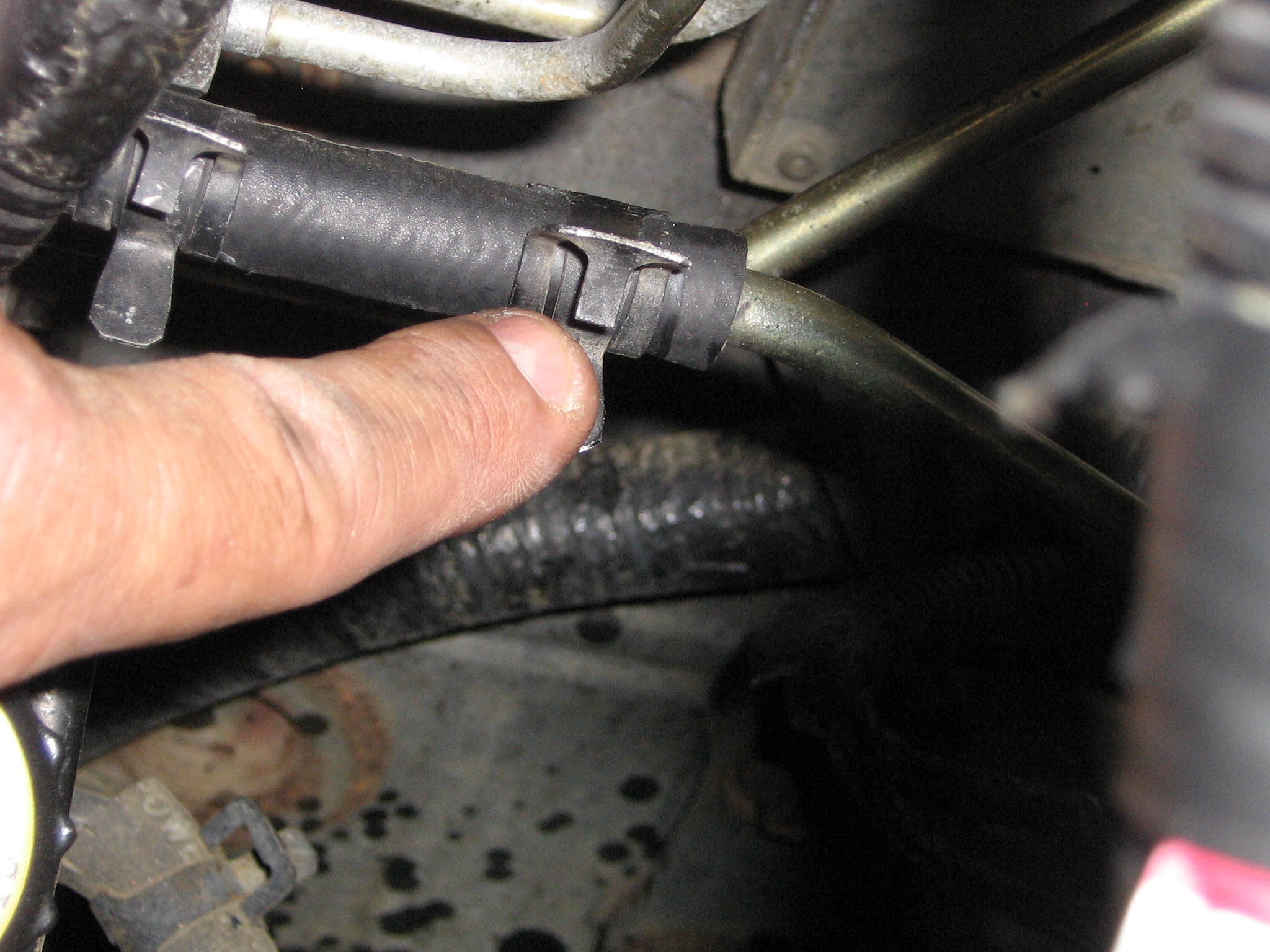

I used the following procedure to test the flow rate on my truck. There is a short piece of ¼” flexible fuel line between the filter housing and the injector pump. I removed this fuel line by loosening the clamps and sliding them out of the way and then pulling the housing off of the metal tubing.

I then connected the piece of ¼” clear tubing to the outlet side of the filter housing by sliding the clear tubing onto the metal tubing and clamping it. The other end of the clear tubing should be placed into the clean graduated container. Once this is done, you should turn the ignition switch to the “ON” position and bump the starter. DO NOT START THE ENGINE. All you want to do is move the fly wheel so the lift pump will cycle on for 25 seconds. Once the pump turns itself off, pour the collected diesel fuel from the graduated container into the fuel container. Try not to let the fuel in the tubing run out. This dispense does not count because you are priming your test system and it may not have enough fuel in it. Now place the end of the clear tubing back into the graduated container and bump the starter again. You should see fuel flowing almost immediately. Watch this fuel for air bubbles. You should see some bubbles but not a lot. Once the pump turns off, look at the container and see how much fuel was dispensed. You want a minimum of 45 fluid ounces with very few bubbles in the fuel. Once you have checked this, you have completed this part of the test. Regardless of the amount you get, I would suggest you repeat the test a few times and record the results. I ran the test 5 times and took an average of the readings. Again you should get a minimum of 45 fluid ounces each time. If you do not get the minimum amount of fuel, you have a problem with your lift pump. It either has failed or is failing, and should be replaced.

An excessive amount of bubbles in the fuel indicate your fuel system is leaking and pulling air into the system when the pump is running. If you have a lot of bubbles in your fuel, you should check the fuel lines and fitting between the fuel tank and the lift pump for leaks. Correct any issues found.

My truck had a fuel pressure reading of 4 psi at the filter housing and 3 psi at the injector pump. The fuel volume from the life pump was 0 fluid ounces. The reason I have a pressure reading but no flow from the lift pump is because the injector pump will pull fuel through the system and build some pressure. These two tests indicated I had a lift pump that had failed. I went to the local parts store and purchased a new OEM replacement lift pump. I installed this pump using the procedure in part two of this article.

Woodbutcher

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2009 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.