What is TIG welding?

TIG welding is a shortened name for Tungsten Inert Gas

welding process. The AWS official name

is Gas Tungsten Arc Welding or GTAW. Names such as HeliArc or Heliweld

are "brand" names given to this process by manufacturers of TIG machines

or supplies.

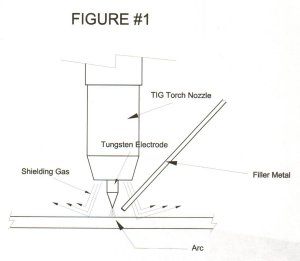

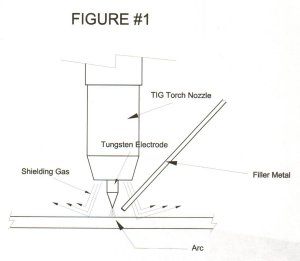

TIG welding is a shielded arc welding process very similar to MIG (wire)

welding except that the arc

is not provided by consumable wire but a non-consumable tungsten electrode.

On TIG weld joints requiring filler or reinforcement, filler metal is added

from outside of the arc either by hand or small, automatic filler rod feeders.

As said previously, the TIG welding process uses a tungsten electrode

to conduct electric current

to the arc, creating a very precise and local heat zone. This makes

the TIG welding process ideal for use where it is critical not to heat

very large areas.

The TIG weld puddle and electrode are protected from atmospheric contaminants

by a shield of inert

gas. The inert gases used in this process are Helium and/or Argon.

Inert gases do not combine with atmospheric gases which make them ideal

for shielding the weld puddle and heat zone. (Fig.1)

The TIG Welding System

Power Source

The TIG welding power source should be a AC/DC welder with a high duty

cycle (60% duty cycle

minimum). This welder should also have a HIGH FREQUENCY or HF generator

either built into or added onto the machine. Lincoln Welding makes a very

nice add-on high freq. box that will allow you to turn an ordinary buzz

box (AC/DC) into an excellent TIG welder. The High Frequency feature is

necessary to maintain a stable arc during the "zero" voltage conditions

in the alternating current cycle.

TIG Torch

The TIG torch is designed to deliver both electric current and shielding

gas to the weld joint. When

shopping for a torch, be sure it is a brand that has been around for

a while so you will be able to purchase parts for it in the future. Stay

away from the brands sold by the "tool guys" (Snap-on, Matco etc.). These

brands are notorious for replacement part delays or inavailability.

The torch is by far the most important purchase of your TIG welding system. I cannot stress this enough!

A torch that stays cool and fits comfortably in your hand can make the difference in the integrity of your welds. There are quite a few options on the market now, so be sure to look at all of them. Be sure to purchase collets for the electrode sizes you will be using (see TIG Electrodes).

You can get air cooled or water cooled torches. Torches are rated by amps. Air cooled torches get extremely warm while welding. A good rule to go by when purchasing an air cooled torch is to purchase a torch rated at 150% of your welder's rating. Water cooled torches are a must for production applications or extremely high amperages but are impractical for the hobbyist.

Inert Gas System

This one's simple. A bottle of pure Argon will cover all but the most exotic welding applications. Helium is also used in this process but (I believe) it is more expensive.

You will also need a Flowmeter/Regulator. This type of flowmeter has the glass tube with a metering ball that visibly shows the rate of flow for your particular gas mixture.

TIG luxuries

If your welder has the "remote amperage control" option you can add a foot pedal to your system. The foot pedal allows the operator to adjust the amperage while welding. This is a great option and a definite must for multi-position welding.

If you don't have the "remote amperage control" option, you should get a simple push button control that allows you to shut power off to your torch until you are ready to strike an arc. This button simply tapes to the top of your torch in a comfortable position and can save you from accidently striking an arc.

TIG Electrodes

Three different grades of electrodes are used in the TIG welding process: pure tungsten, 1% thoriated, and 2% thoriated. Pure tungsten electrodes are general use electrodes, good for all types of steels.

Thoriated electrodes provide a "cleaner" arc, last longer and tend to restrike with a more stable arc. Thoriated tungstens are for non-ferrous work. I keep pure tungstens on hand for steel and 1% thoriated on hand for aluminum welding.

Tungsten electrodes are available in several diameters: .040", 1/16, 3/32, 1/8, 5/32. 3/16, and the whopping 1/4". I've used 3/32" and 5/32" diameters exclusively and would recommend the same to anybody.

TIG Filler Metals

TIG filler metals are numerically catagorized similar to Arc Welding

electrodes. The most common

filler rods are 36" long and available in 1/16, 3/32, 1/8 diameters.

It is important to remember that oxy-acetylene welding rods are not compatible

with the TIG welding characteristics so be sure to keep them seperate.

I keep 2 types of filler rods on hand for repairs and fabrication of steels: ER70S-2 for general repairs and Lincoln Missileweld for alloy steels. The Missileweld has a stainless steel coating and the ER70 has a copper coating. Aluminum filler metals also come in several grades and will be covered in another article.

Millwright

Return to The Alpha Group Web Page

![]() Send

Warlord E-mail.

Send

Warlord E-mail.

Address:

All materials at this site not otherwise credited are Copyright (c) 1996, 1997, 1998, 1999, 2000 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.