*Installing Vertical Blind*

By: John1lt

28 APRIL 2019

I apologize for the poor quality of the pictures.

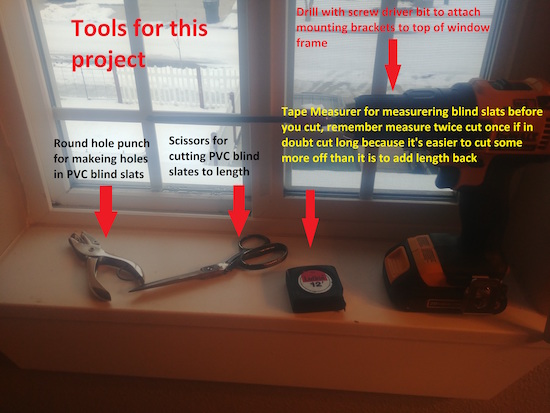

When I managed apartments we changed out the drapes to vertical blinds as we cleaned up the units. Home improvement stores will cut the head rails and PVC blinds to custom lengths. Our contractor would have the store cut all the head rails and some of the blinds to length. The blinds come in various lengths so he would buy blind slats that were for sliding glass doors and use those for windows, the blind slats were 2 times or more longer than needed. After the store cut the blind slats down he would take the extra length and bring it back to the apartments and use a hole punch to make the hole that is used to attach the blind slat to the head rail. Our contractor also used a power miter saw with a fine tooth blade to cut some of the blind slats, he would tape a bundle of slats together in a stack and put tape around the stack where he was going to cut to prevent tear out. Using the power saw made quick work but it also melted the slats together but were easily pulled apart with no damage and a sharp utility knife cut off any melted PVC attached to the end.

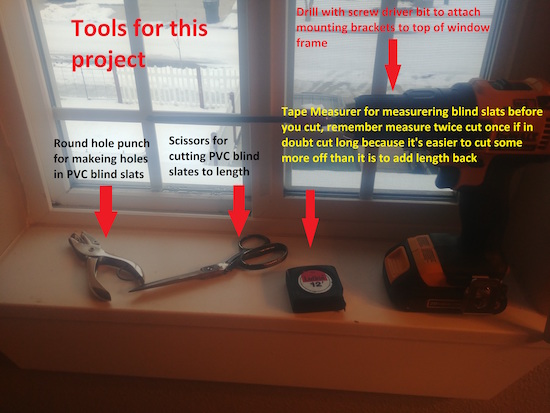

After we purchased our house I wanted vertical blinds in my office and bathroom, our house came with trashed mini blinds and a few nasty drapes. I went to the home improvement store and found some head rails. I had the store cut two head rails for the windows. The slat sizes offered at the home improvement store were too long for my windows. Since I was mounting the blinds inside the window frame and the people at the store couldn't tell me how much to subtract from the length for the blinds I opted to buy one package of slats and cut the slats at home using the extra length to make the additional slats I would need.

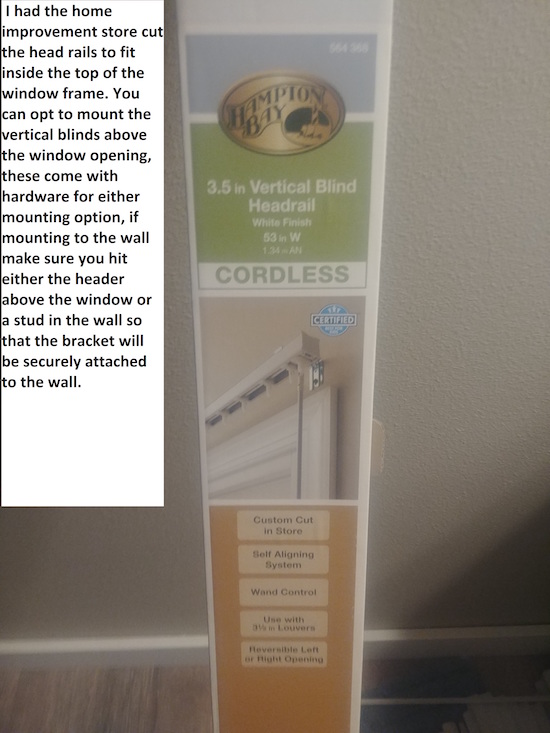

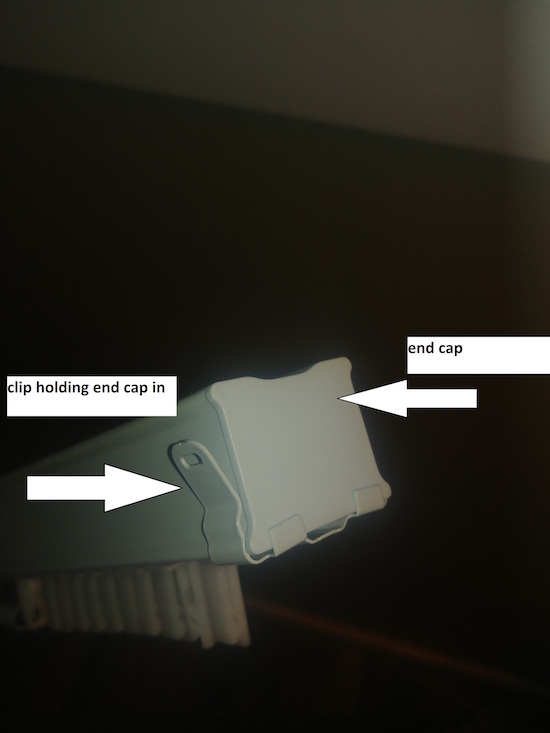

At home I removed the L brackets from the clips that attach the L bracket to the head rail. I screwed the clips to the top of the window frame far enough from the window that the blind slats would not be touch the window when in the open position. After that I pushed the head rail into the clips until it clicked and the clips were fully engaged in the head rail.

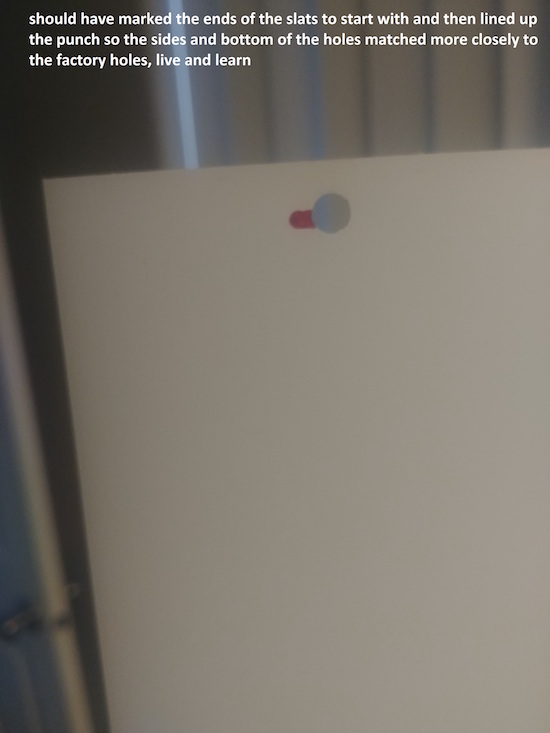

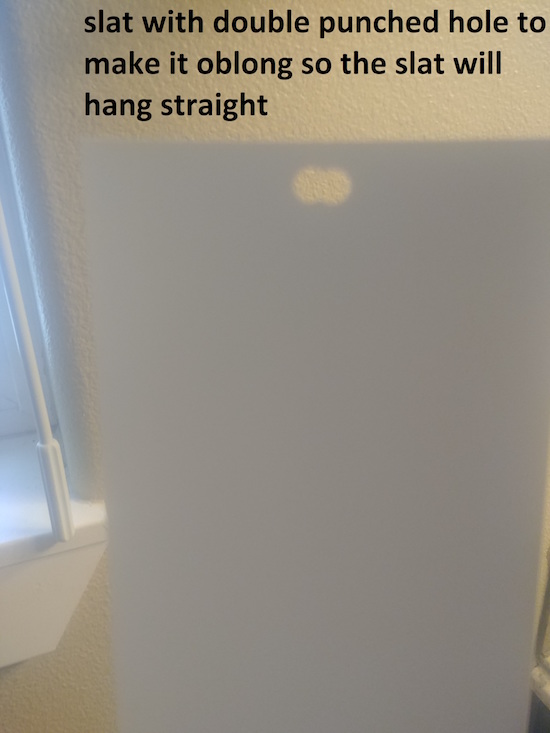

After mounting the head rail I measured for the slat length and cut individual slats one at a time with scissors. I used the top of the slats with the factory hole first. When I ran out of tops I took my hole punch and put holes in one end of the remaining slat ends and hung those. I originally only put one round hole in each of the slats but when I hung these the slats didn't hang straight down, the single hole was big enough to fit over the clip in the head rail but since it was a round hole instead of an oval hole it caused the slats to hang at odd angles. I had forgotten that when using the round hole punch I needed to put two holes side by side creating an oblong hole so the slats would hang straight down. I used a slate with a factory end to mark the hole position on the DIY slats then used my hole punch to widen the holes, something I should've done to begin with.

After all this I discover I should have attached the plastic brackets for the valance that hangs in front of the head rail to the head rail before clipping the head rail into the mounting brackets. It was an easy fix but I saved a little effort and time on the second window by putting the valance brackets on the head rail before clipping it into the mounting brackets.

When I managed apartments and the hole on the end of one of the blind slats ripped out I would use a hole punch to make a new hole in the bottom end of the slat and flip it over. I would put the damaged slat in the last clip on the stationary side of the head rail so it was less noticeable, this satisfied most tenants since I didn't charge them for the repair unless they insisted on new slats. The long slats for sliding glass doors seem to be damaged more often than the slats used in windows so if I had several damaged slats I would save those to cut down and use in window blinds later.

I used my office hand paper hole punch for this project, 25 cents at a yard sale or $1 at the office supply store. They make a specialty hole punch for blind slats I just couldn't see spending $15 on a tool I would only use once every ten years and probably misplace between uses. If something not being exactly perfect bothers you then you might want to spend a couple of bucks for one so the size and shape of the hole looks factory, I think these might also position for distance from the end of the slat but I've never used one so I cant say for certain. You can buys these hole punches at home improvement stores or on Amazon.

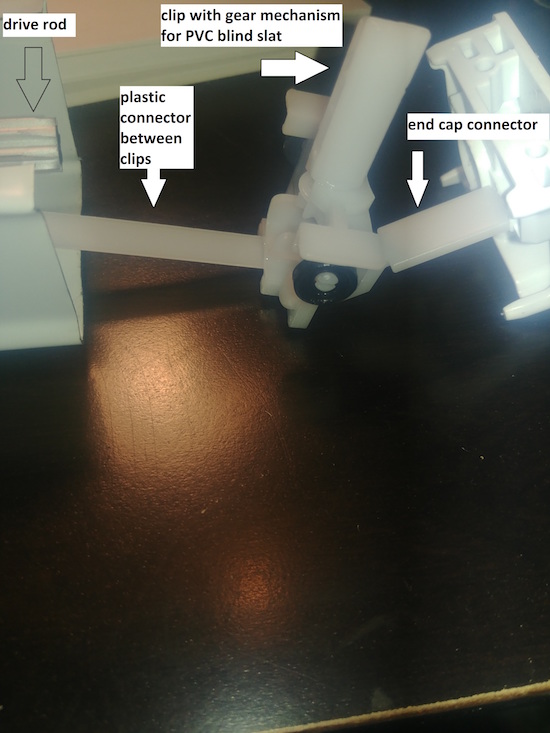

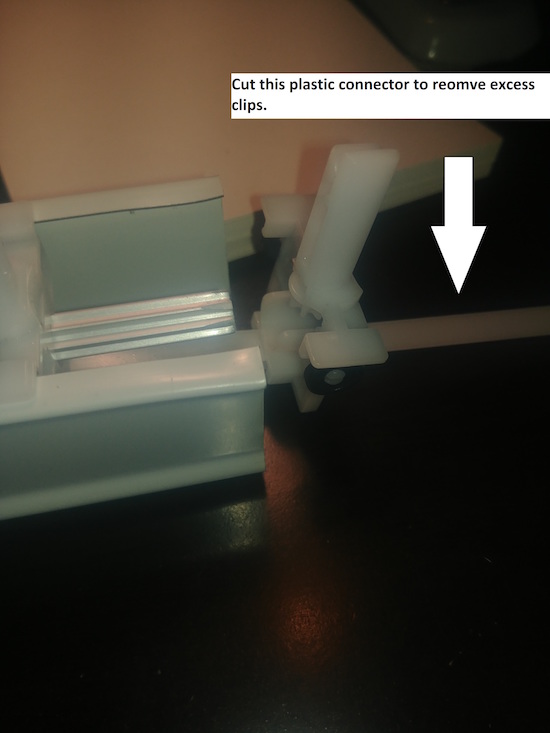

On one head rail the guy at the store left too many clips for the slats in the rail, it looked bad with a bunch of slats bunched together at the stationary end of the rail. To fix this I popped the end out of the rail and pulled a few of the clips with the gear mechanism out of the end and used a pair of scissor to cut the plastic tab that connected the clips together removing the extra clips.

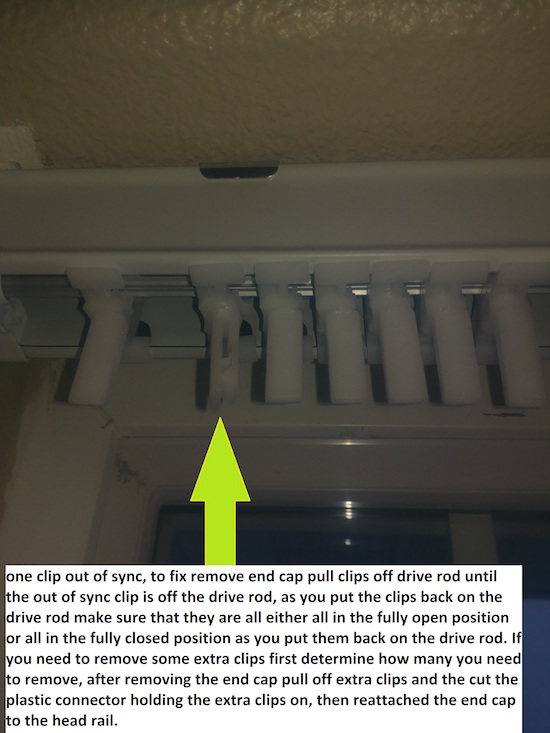

One of the clips was out of sync with the others, must have happened when the guy at the store put the head rail back together after shortening it so I took this opportunity to pull the clips off the drive rod and set them all to the same position as I slid the clips back onto the drive rod. I put it back together made sure it functioned and hung everything back in the window. It looked much better without 4 extra slats bunched on one end.

My blinds don't look professional, I can see the slight variations in length from hand cutting and some have a little angle to the cuts. The blinds do look good from the street. This was just an inexpensive solution to the issue until we save up money for nice window treatments.

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2019 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.