*Freeze-Dried Food (Part 1)*

By: RedDon

30 January 2012

I have been preparing for several years now and have several methods for storing food. I use cans bought from the store, vacuum sealed plastic, vacuum sealed jars and canning (jars). Additionally, I keep a good stock of MREs. Besides convenience, I feel that the advantage to multiple food storage methods is that if any one method doesn't turn out as expected, there are several others to fall back on.

A new method that I recently decided to check into is freeze-dried foods. I heard a few bad things about this method such as digestion issues and cost. But, having an additional method sparked my interest especially since freeze-dried foods can be stored for a much longer time frame than my other methods (up to 25+ years). So I experimented with various samples and was quite happy with the results.

I decided to write an article on this topic and it is in two parts. This article is Part 1 and is a presentation involving the definition, history and process of freeze-drying and the availability of freeze-dried foods. Part 2 discusses my actual results of sampling freeze-dried products which includes advantages and disadvantages.

DEFINITION:

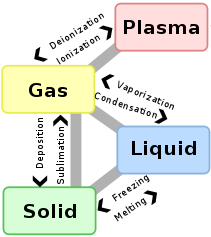

Freeze-drying is the removal of water from frozen food. It is also called Lyophilization, which is the process of drying something out without damaging or altering its internal structure. It is basically used to dry materials which are sensitive and delicate substances. The fundamental principle in freeze-drying is sublimation.

Sublimation is the shift from a solid directly into a gas and occurs when a molecule gains enough energy to break free from the molecules around it. Water will sublime from ice (solid) to vapor (gas) when the molecules have enough energy to break free but the conditions aren't right for a liquid to form. Two variables that are important for this transition are heat and pressure, where they must be within certain precise ranges for a substance to take any particular phase. Without these conditions, that phase of the substance can't exist. The precise control of these variables is one reason why freeze-drying machines are so expensive.

HISTORY:

Freeze-drying can be traced back to ancient times in Peru when the Incas stored food in the Machu-Picchu mountains.

At high altitudes, the food was frozen and because of the lower air pressure, the water in the food evaporated, thus preserving the food. The military used freeze-drying during WW2 to preserve plasma and penicillin. NASA used the process to send food to space with the astronauts. And of course freeze-dried foods became commercialized and very popular for hikers and those who want to store food long-term.

PROCESS:

A typical machine consists of a shelved chamber, a refrigeration unit and a vacuum pump. The material to be preserved is placed on shelves while it is still unfrozen. The machine runs the compressors to lower the temperature in the chamber where the material is frozen solid. This separates the water from everything around it on a molecular level, even though the water is still present.

Next, the machine turns on the vacuum pump to force air out of the chamber, lowering the atmospheric pressure. The heating units apply a small amount of heat to the chamber causing the ice to change phase. Since the pressure is so low, the ice turns directly into water vapor. The water vapor flows out of the chamber and condenses onto the freezing coil in solid ice form, in the same way water condenses as frost on a cold day. This continues for many hours or even days while the material gradually dries out. As the water is removed, pockets are created which leaves the substance at the same relative volume and aids in its reconstitution later.

The process takes a long time because overheating the material can significantly change the composition and structure. Additionally, accelerating the sublimation process could produce more water vapor in a period of time than the pumping system can remove from the chamber. This could rehydrate the material and somewhat degrade its quality.

Once the material is dried sufficiently, it is sealed in a moisture-free package, often with an oxygen-absorbing material. As long as the package is secure, the material can sit on a shelf for years without degrading until it is restored to its original form with water.

Because of the precise conditions needed, freeze-drying is a complex process requiring specialized equipment. There are no home freeze-drying units commercially available for normal consumer purchase. The expensive equipment is normally found in laboratories or commercial freeze-drying companies. When products for consumption are produced by these companies, it has to be approved by the Department of Agriculture.

AVAILABILITY:

There are a wide variety of freeze-dried foods available that come in a variety of packages. And it is not difficult to find companies that sell freeze-dried products.

Just about any type of food can be freeze-dried except foods with high water content such as watermelon and lettuce. When reconstituted, foods will retain their original state and texture. And as stated, they retain their flavor and nutritional value. Pictured below are examples of food that has been freeze-dried. The first picture is a sample of diced chicken and the next picture is a comparison of spaghetti in its freeze-dried and its reconstituted states.

Reconstituting freeze-dried food does not appreciatively increase food volume but rather fills the pockets created by the freeze-dried process.

The most popular packaging techniques are pouches and cans. Pouches are convenient for hiking while cans are popular for long-term emergency storage.

Pictured is an example variety kit of several entree pouches and a #10 Can of Diced Chicken. Available types of food per container can range from meats, vegetables, fruit, entrees, drinks and even deserts. There are even breakfast menus available including cheese and milk.

Finally, there are numerous companies that sell freeze-dried foods and convenient purchases can be made via the internet or in stores that sell outdoor products. My next article (Part 2) centers on my choice of three online companies and samples of their products. Just to note, I have no vested interest in any company offering these products for sale.

RedDon

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2012 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.