*Portable Auxiliary Water Supply and Storage*

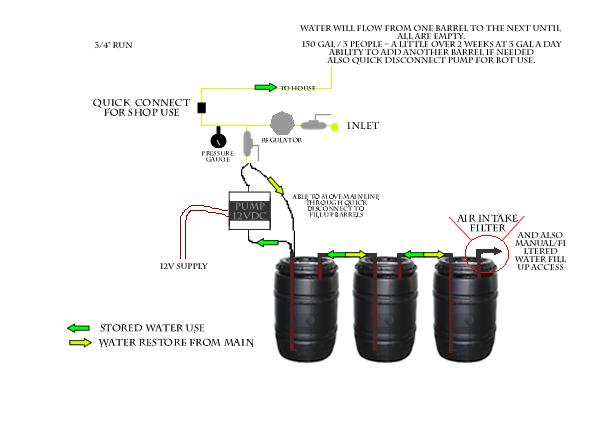

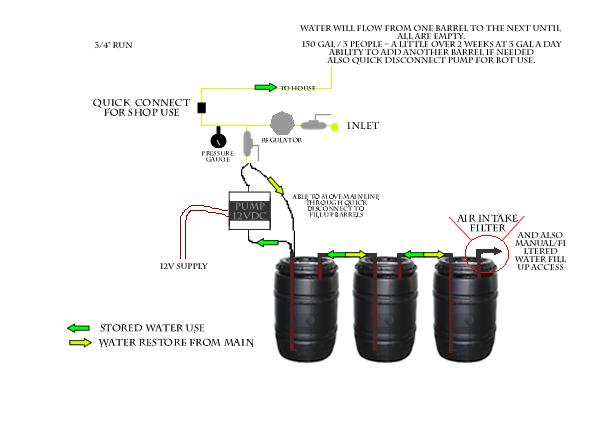

This article was inspired by Spitfire’s Zero Disruption Water and Supply and Jumbo Zero Disruption Water Supply articles. My goals when designing this system was to 1) have an integrated system for whole or partial house pressurization. 2) Make it nonpermanent for possible bug out scenarios. 3) Must be 12v powered. 4) Can unhook and go in under 5 minutes. 5) Must keep a small foot print. This is the drawing I came up with. I made certain changes along the way but can keep my house pressurized and keep my family in water for 55 days with strict water rationing and over two weeks with a 3 gallon a day limit.

I recently needed to change the Main water valve coming into the house due to it leaking and not able to shut off the water completely to the house. So I put in a whole house filter and 2 extra legs for the auxiliary water setup.

The leg on the left is continually attached to the pump for back up use and the leg on the right is used for barrel refill or shop use. On the end of each leg I attached a hose quick disconnect I purchased from Home Depot. So the pump assembly can be removed quickly without tools and placed on the BOT.

I placed two lags with T hand screws. So I could un-mount the pump without tools and mount it on the BOT quickly. These are replacement T nuts that Lowes sells for your lawn mower push bar.

This is the entire system in perspective. The last barrel needed connecting in the pic on the right. This has since been done. One of the concerns that was expressed with a system placed in series is that the draw would collapse the barrels. I took this into account with larger ¾” runs between the barrels and to the pump. There was slight movement (shrinkage) in the barrels but not enough to concern me at this time.

This is a pic of the barrels being filled.I did notice that when filling the barrels that if I used the full house pressure the lead barrel would swell considerably when filling the next barrel. To combat this, decrease the inflow to the barrel.

The PVC was attached to the bungs with Teflon and an O ring,

A length of PVC was used to reach the bottom of the barrel

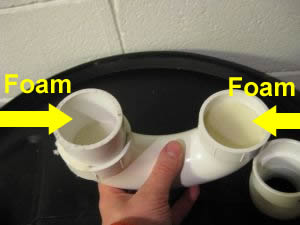

The vent was made from parts purchased at Home Depot. I used some foam for a filter. It is in two places and easily filters large contaminants while letting the air flow freely.

The PVC adapter for the vent was purchased from USPlastics.com for around 2 dollars.

The power box was created from a project box from Radio Shack. The pump needed a 25A fuse so I put one in (4) and added 2 LEDs to let me know what was happening with the power. (2)(3) The terminals are generic for use at home or in the field. (1)

If all lights are off then no power is getting to the pump/control box. If the yellow LED is lit then the unit has power but the pump is off. I thought this was important for my on-demand ShurFlo pump. I can see myself thinking it was off. If the Pump is on then all LEDs are lit. I designed it this way so I can see at a glance if the pump is on and make troubleshooting a little easier if needed. If the fuse blows then all LEDs would fail to light also.

Thoughts: I got the pump for a song at a resell place. It looked like new, and each barrel was also for a song, new but seconds. The pieces and parts both electrical and plumbing were purchased at Lowes, Home Depot, RadioShack, and USPlastics. The pump can be taken into the field for water collection from a water source in to your collection container. It sure beats hauling and dumping 5 gallon buckets and it lessens the time spent in the open and vulnerable.

Turchin

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2009 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.