*SPEEDdraw Knife Mod*

A weapon is only useful if you can deploy it in time to use it...in close-quarters combat that either means you were VERY alert and pulled it beforehand; OR, under the adrenaline-dump stress of combat your weapon must be deployable FAST with just a simple movement. (fine and complex motor skills tend to go *poof* under adrenaline stress).

Emerson knives developed the "Wave" to answer this problem. Start with a pocket-clip knife, add a specialized sort of stud that catches the pocket and opens it AS it is pulled, with no effort from the user other than pulling the knife in a rearward draw.

Emerson "Wave" knives are pretty expensive though. A strain on the budget for many of us, and if you lose one, you've lost quite a chunk of change.

However, if you own a Dremel tool (which every survivalist should;) you can modify any thumbhole-opening clip folder knife into a "Wave"-type opening knife! Yes, you can buy a $10-$40 thumbhole-flick clip knife "Wave" it, saving yourself about a hundred bucks per knife.

Credit where credit is due: I didn't invent this modification, I learned it from a knife-customizer named M. Atwood, who posts elsewhere on the Net. Thanks to M. Atwood!

You'll need: A thumbhole-flick-opening type pocket-clip folding knife...I used a Spyderco Delica, which is perfect for this mod. The knife needs to have the pocket-clip positioned for bladetip-UP carry, or else you'll need to move the clip. If you do have to move the clip, one simple way is to attach it with J-B Weld, a metallic epoxy of remarkable strength.

One of the great things about the Spyderco Delica (of many!) is that its clip attachment is "ambidexterous"....great for me, because I wanted this to be a "left-hand blade". I'm not left handed, no...but I wanted something I could pull lefty in case my right hand was otherwise occupied (tactical consideration...my right hand is for firearms, left hand for knives;-)

You'll also need a Dremel, which is a small multi-use power tool, commonly used for small-scale cutting and grinding. For Dremel accessories, you'll need a cutting wheel (cut-off wheel), and a disk grinder attachment...a polishing attachment is also nice for prettying-up the results. There are other tools that would do, such as a hacksaw and belt sander or bench grinder, but I like a Dremel for "fine work".

The other things you'll need is a large shallow dish/bowl of water, to dip the knife in for cooling purposes during the work, and a soft cloth to wipe it with.

This is my Dremel, with the cutting wheel attached, and other accessories:

This is a picture of a Spyderco Delica, in its "pristine state":

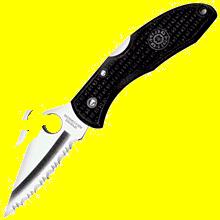

This pic shows what we're going to remove from the blade:

Cutting proceedure: This is important: work with the KNIFE CLOSED!! If you ignore this rule and cut your fingers off, don't come crying to me! Keep that blade closed!!

Use the cutting wheel to cut completely through the thumbhole in two places: center-top, and nearest the front of the thumbhole. You'll need to use high-speed setting on the dremel, but work SLOW, cut for a few seconds then dip the knife in the water. If you don't pause to dip the knife in water every 5-15 seconds, you risk heating the blade and ruining the temper, or damaging the handle though trasnferred heat!

It is best to use a fine-point magic marker to draw your cut-lines...this helps keep them "clean".

Be VERY CAREFUL as you complete the cut to remove a piece of metal...at the moment of seperation, the cutting wheel can jam and break, or the piece of metal may fly off in a random direction! Wear eye protection, and as you're working on the last *tiny* sliver of steel holding a piece, switch to Low speed on the Dremel.

Now, you've opened the thumhole to create the "wave" that will catch the pocket-lip and flick the knife open...but with most blades there's still a problem. The curve of the spine as it rises to the thumbhole can cause the lip of your pocket to miss the "wave" protrusion, deflecting it and causing failure of the draw. Don't want this to happen when Manny the Mugger is almost on top of you! Trust me on this, because I tried it with just the thumbhole cut-out: we've got to lower and straighten that spine.

Mark a line to take a sliver of steel off the back of the blade...say about 3/4" to 1 1/4" long, depending on the blade length, and maybe 1/8" or so width. You want it to be level with about the middle or upper third of the thumbhole. Look at the pics again to get the idea.

The easiest way I found to do this was to cut a line into the side of the blade, working the cutting wheel linearly along the line and through the metal evenly. Again, pause frequently to dip that blade in the water!

Now, you're almost finished...use the grindstone wheel attachment on your dremel to de-burr, smooth and straighten where you've cut. Then, if you like, use the polishing attachment to pretty up the finish of your cuts.

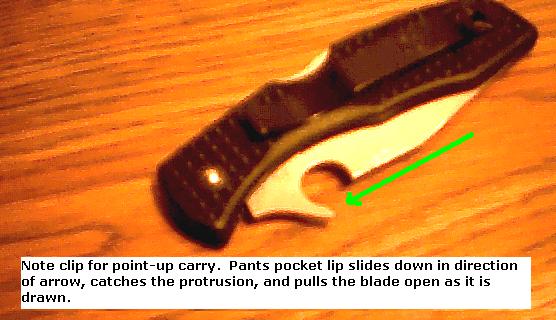

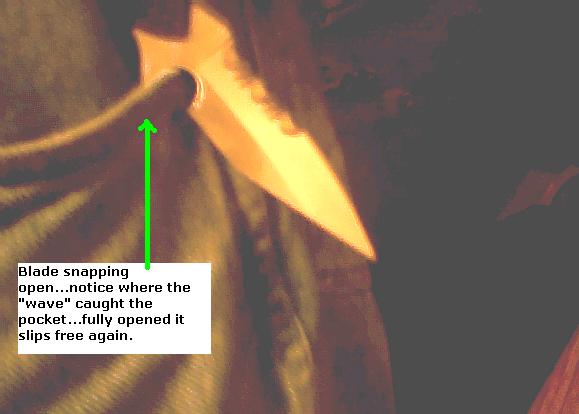

Drawing the knife: clip the knife in your pocket. Remember, it has to be blade-tip-UP for this to work! As you pull the knife out of your pocket, simply either 1. pull back toward the rear of your pocket a little, or 2. twist the handle a little so it bears on the outside lip of your pocket. This doesn't require dramatic pressure, just a little, and the blade will pop open as you draw it! Very fast, very simple...what you need for good tactical deployment.

Here are some pics of my actual finished product, and of the draw.

There you go...have at it, just be careful!

Goshin

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2003 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.