*Replacement Grinding Wheel for a Hand-Crank Grinder*

By: GVI

29 June 2023

Note: This article is a followup to GVI's previous article on constructing a "Level Table": Level Table: A Simple Project With Many Uses. In this article he describes using the table to solve a bushing availability problem.

In a previous essay, I discussed a hand-crank bench grinder. It had replacement wheels, but they had the wrong-sized hole for the grinder's spindle and the exact bushings I needed are hard to come by. A knowledgeable Amishman directed me to an answer I should have come up with on my own, but that's how things work sometimes.

All the elements I needed in order to complete this project finally fell into place; and now that I could proceed, this essay discusses how it went.

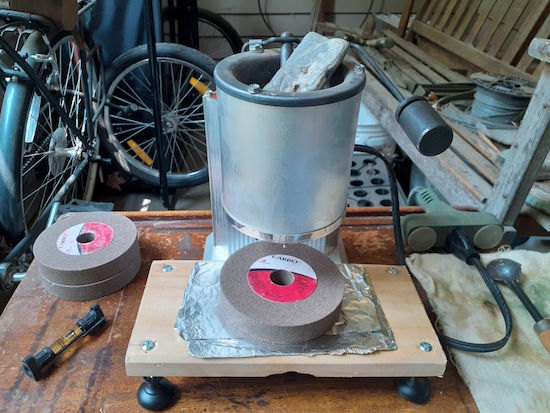

The first step was setting up to pour the babbitt metal into the holes. Here's a photo of what I used:

I do my casting on my front porch, on a child's school desk that's been around so long I can't remember how it came into my family's possession. If you look carefully, you'll see the spirit level from the previous article, and you'll see how my porch pitches down from the house. This is why I had to make the little level table.

I set up the level table underneath the spout and leveled it according to the method I laid out previously. The bubble needed to go to the left, so I rotated the feet both out (with my left thumb moving to the left), until the bubble was carefully centered.

The level was then lined up on the opposite pair of feet and the procedure repeated.

Once the table was leveled, the furnace was plugged in and the metal melted in the common manner. Whenever I cast anything, I put a piece of aluminum foil underneath the spout because as you can see, my furnace has gonorrhea.

Nothing a shot can't cure

The pouring went fine but the first one (upper left in the following photo) was a bit of a botch in that the hole didn't fill fully or properly. The other two were fine, and the "bottom" simply looked like the aluminum foil underneath them.

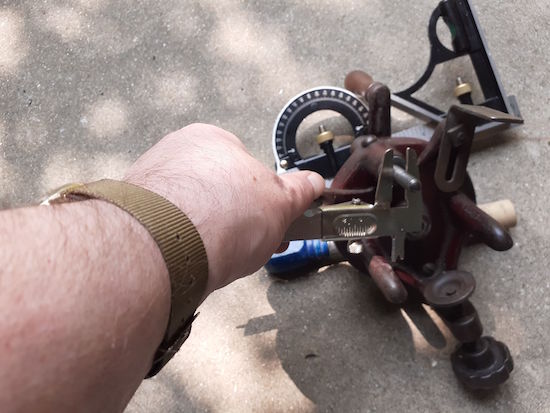

The next photo shows something I bought on a lark and never thought I'd use. I already have a combination square, but one day at Harbor Freight I saw this combination-square-on-steroids and picked it up. It turned out that square-turned-sideways doohickey was exactly what I needed in order to accurately locate the center of the wheels for punching. I use the calipers all the time and needed them to measure the grinder spindle and drill bit (drill bit sizes are best thought of as "nominal," though they're not as fictional as "nominal" lumber sizes).

Finding the center of a circle is easy with the center-finder-doohickey, and babbitt metal is easy to punch.

Now it was time to drill the holes. The best thing for this kind of work is a drill press, and just a few weeks ago I got my "post drill" hand-crank drill press back from a Lodge Brother. He had offered some time ago to sandblast it for me, but he soon took ill and could not finish the work. I got it back more-or-less in the shape I'd given it to him; and while I'd rather have had it all spotless and shiny, ready to be painted, I can't hold it against someone when misfortune overtakes them. So for now I'm content with the thing having a rust patina but all the working surfaces cleaned and oiled/greased. I didn't get it just for this project; in fact, I bought the post drill before the grinder. It's just been away for a long time.

For the idle curious, it's a Champion Blower and Forge No. 102

There is a learning curve to drill presses. The first wheel - the one where I botched the pour - was used for practice and, true to form, I botched the hole. The other two went much better.

The waste went right back into the pot. It'll make very hard wadcutter bullets

Last part was installing the wheels and dressing them. They're dressed with a slight curve for two reasons: first, because the only thing I'm using these for is chisels, planes and screwdrivers, and a curved grinding face makes the work easier. Second, grinding off the edges gets them to fit on the grinder with a bit more clearance for the mounting bracket.

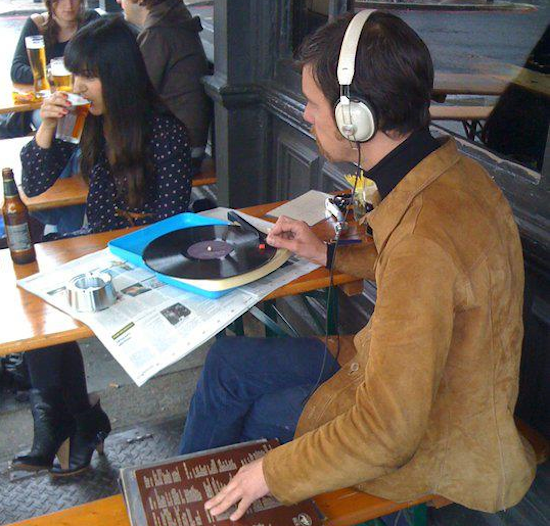

In my insistence on only having hand-powered tools, I accept the likelihood that on the surface I bear at least a passing resemblance to those with similar affectations:

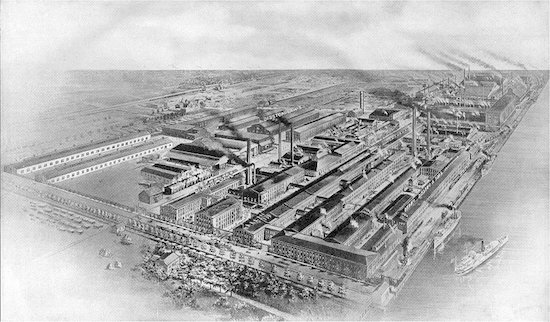

Am I a "hand-tool hipster"? Perhaps. I'm mature enough to know that high-minded statements like "Exploring the boundaries of what's possible" or "Appreciating the craftsmanship of pre-industrial toolmaking" are rationalization in the first case and snot-nosed sanctimony in the second. "Exploring what's possible" is simply rubbish - the hand-crank drill press by its existence proves what's possible - only an imbecile would build a factory to cast 65 pounds' worth of iron into that shape if he wasn't certain the damned thing would work. As for the second statement, the tools I own are unquestionably Industrial-Age. I've spoken before about how the artifacts "old-tool-aficionados" drool over weren't lovingly made in some artisan blacksmith's forge like a bespoke Japanese sword, but rather in large coal-fired factories with their own rail spurs and riverside docks.

Where the best hand saws in the United States were made

And yet, following the Amishman's suggestion and making my own bushings for these grinding wheels does indeed "explore the boundaries of what's possible," because heretofore I had never given consideration to the method. And while the solution sprang fully-formed, Athena-like, from the mind of this clever craftsman, it's possible he just came up with it in a moment of creative genius.

That I did this all without the aid of power tools (I exempt the lead furnace because I'm not a single-minded lunatic) is secondary and subordinate to the fact that I made something which, in my mind at least, had never existed before. The prepper side of me sees this simple solution as more than merely the practical act of solving a problem, but also as a symbol of the fact that we - by which I mean humanity generally - do not need ready-made solutions, but can conjure new ones up as and when we need them.

A good friend of mine collects old blackpowder centerfire rifles of the sort used between the American Civil War and the Spanish-American War. She allows as how many of them, for which cartridges can no longer be made, have passed from the realm of usable artifacts to that of tchotchkes, simply because they're unshootable. What I did with this bushing-business was take an item which was at risk of becoming just such a tchotchke, and turned it into a usable and relevant artifact. For the philosophical, there's meaning there - and I leave it to you to find it.

GVI

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2023 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.