*Welding Personal Protective Equipment (PPE)*

This is intended for those who have little to no knowledge of welding. If you're going to start learning you need to be safe.

Welding is a dangerous process. There is risk of electrical shock, burns from both hot metal and ultraviolet light, eye damage and even falling material. Wearing the proper protective equipment will greatly reduce the welder's risk of injury. Steel toed boots, a leather welding jacket or a leather cape bib, jeans or other less flammable material, thick leather welding gloves, safety glasses, a welder's cap, foam ear plugs and of course, the welding helmet are what I wear. NEVER, EVER, DON'T, JUST DON'T DO IT wear fleece or flannel type clothing when welding, those microfibers will easily catch on fire and ruin your day. A flannel shirt will flash quickly and envelope your upper body in fire in about 2 seconds.

Even with proper PPE on correctly, things can still happen. My non dominant arm has several burns and blisters on it from doing overhead welding and having hot slag fall on me. The heat transfers through the leather and on to my arm. It'll even burn skin through leather and a sweatshirt, however if the slag was knocked off the leather as soon as the heat was felt, any burn should be minor. I'm used to it so I just keep on going.

So, why wear all of that stuff? That's an awful lot of stuff just to weld. Ok, let's do a breakdown from head to toe.

Helmet - The face shield (helmet) is what protects your face from the ultraviolet rays and extremely bright light caused by the welding arc. There are many different shapes and styles out there. Some have the small window, others have a big window and some are auto darkening. I use a Jackson brand with the small 2x4.5" window with the flip filter. The dark filter is what darkens the brightness of the arc. Filters are rated with a numerical scale. There is a chart that will give you what number shade to use in a certain amperage range. Charts are nice, but the survivalist/Prepper back yard welder isn't going to be running a machine using 325 amps requiring a very dark lens. You'll typically be in the 60-175 amp area. A #10 shade filter will take care of that. #9 and #11 are good to have on hand and only cost a couple of bucks a piece for the 2x4.5" ones. Remember that the higher the number, the darker the shade. you have a #12 and are trying to weld at 80 amps, you aren't going to be able to see a thing. While TIG welding I use a #10 and when MIG or stick welding much above 100 amps, I use a #11. That's what works for me.

Cover lenses are clear plastic lenses that protect the filter plate from spatter. They only cost about .63 cents each so it's much better to replace those than 2-3 bucks at a time. The filter assembly flips up to allow clear view out through the front of the helmet. There MUST be a cover lens in the helmet to protect you from slag or sparks flying through the front of the helmet if you're chipping or grinding. The filter plate should have a cover lens on both sides of it because when it's flipped up, you don't want crap getting on the backside of the filter itself.

NOTE: The cover lenses are INTENDED to be changed. The outer one will get nasty quickly and, if you're welding with your helmet close to the work, it gets bad really quickly. If you CAN'T SEE you can't weld. PERIOD. Remember, you're looking through 3 cover lenses plus the shade filter. If any other lenses get crappy it'll really distort your vision. Taking out one and thinking "oh that looks ok" is a bad habit. Take out all 3 cover lenses and stack them together. Then look through all 3 at once and see what it looks like. Blurry? Dirty? Change them all and it'll make all of the difference.

Safety glasses - Wear them even with the helmet on and down. You never know when something could fall inside the helmet. Hopefully the glasses will protect your eyes. They also serve as a backup in case your helmet is up and you chip something.

Welder's cap -This cap is a flame resistant piece of headgear that is intended to protect your head. Sparks can and will get on your head, especially if you're welding at face level or above. I tend to have slag get stuck on it while welding overhead. If not for the cap, my head would be burnt. There is a flexible bill on the cap which is intended to cover whatever ear might be facing upward when welding in a difficult overhead position.

Ear Plugs - The first purpose, obviously, is hearing protection. Grinders are loud. The second purpose goes right along with the cap. You DON'T want sparks or hot slag getting in an ear. Something getting stuck behind your ear or anywhere on the outer part is bad enough as it burns; but, just imagine it being IN your ear.

Mask - If I'm going to be grinding, I wear an N95 (or higher) mask with a one way exhaust valve. Grinding dust is nasty stuff. After 1 week, my mask is black but I know that isn't going into my lungs.

That covers the head. Don't wear torn clothing or anything with loose threads. That is just inviting sparks to get in the wrong places.

Cape bib - This is a full frontal and full sleeve leather garment. The back is open, which is good for welding in a standing or kneeling position. Lying down and welding you would want the full jacket because rolling over on to a piece of slag isn't fun.

Gloves - You want to have dry gloves. Make sure that the sleeves of your jacket or cape bib are tucked up into the gloves. Anything rolling down your gloves, you want to roll off, not roll in under the sleeves onto your skin. ALWAYS WEAR GLOVES. A guy I know has a nice scar from a deep burn on his wrist. He was going to do a quick overhead weld under a vehicle that would take 30 seconds so he didn't use gloves. A piece of slag fell and landed right on his wristwatch band. It burned his wrist and wouldn't fall off due to getting in under the watch band. Jeans are a good bet to wear.

Steel toe boots - Dropping something on your foot isn't good. Simple logic.

Even with proper PPE, bad things can happen.

I got a bad welding hickey one day, even with everything on. I was welding overhead with a 3/32" rod and, since it takes a couple of seconds for it to get hot, I started on the starter strip of the plate so it would be hot before starting my pass on the joint. The rod is also wiggly at 14" long so right after I lit it, it wiggled and a glob of hot molten metal fell. It somehow got inside of my collar. A weld pool can be around 11,000 degrees Fahrenheit so that metal was hot. When it hit my neck you've never seen a fat boy move so fast. I threw down the electrode holder and leaned forward and started shaking. I felt it start going down. It last bounced off my gut just below my belly button before falling out of my shirt. AND THAT IS EXACTLY WHY YOU DON'T WEAR TUCKED IN SHIRTS OR PANTS WHILE WELDING!!!!! I wound up with a nasty burn on my neck and a track line all the way down my chest, a bounce on to my gut and then a nice burn before it fell out. I keep an anti-septic cream in my tool box for such mishaps.

Always "dress down" so that stuff will hopefully roll off or at least shake out in a hurry. You don't want hot metal getting trapped in your clothes. I think a Nomex hood will resolve that hickey problem from happening again.

Here are some photos of masks, my helmet and lenses, along with the shade filter.

You can see how the front flips open to expose a clear cover lens. I flip it up like that for grinding and chipping and obviously flip it down to weld.

Shade filter in the middle in a rubber gasket with cover lenses on either side.

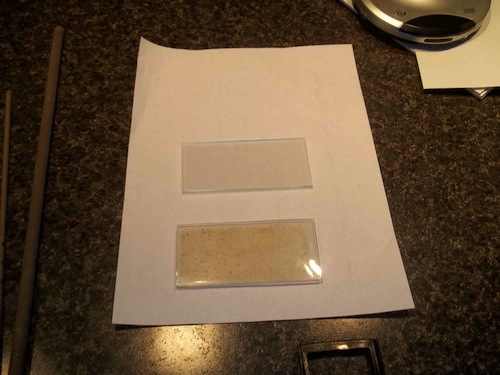

In the left, the lens I'm holding looks clear. You can see the counter through it. However look at it on paper compared to a new one.

The cover lenses protect the shade filter. If you don't use them your filter will look as nasty as the lens shown above.

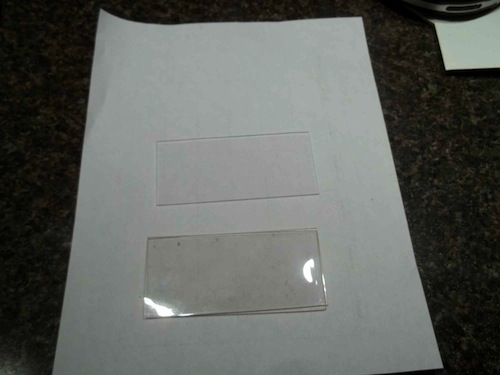

The top shows 2 new lenses stacked, compared to the 2 inner (stacked also) ones I took out of my helmet. Yeah, one is warped from heat.

Here are 3 new stacked and the 3 old stacked. Quite a difference isn't it?

Here's a mask comparison after 3 days of use.

That's gross. Without a mask, that crap goes in your nose, mouth and lungs.

Eli

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2013 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.