Yes, those are two horses…pretty neat huh?

*Abrasive Water Jet Cutting*

Figuring some of the types of projects Rubies get themselves in to, sometimes specialty tools or parts would be nice. Need a specially shaped wrench to make something easier, water jet it. Need precision made copper buss bars? Water jet it. Want a nice custom commo rack for your BOV? Water jet it. Need a gear that you can’t find anywhere? Yup, water jet it. Cost varies depending on material, time and resources used obviously

This thing is neat, I want one when I grow up. I’m doing some work for a guy who owns a water jet shop and he can make just about anything. Material ranges from thin plastic to Lexan, to rubber, to glass, to aluminum, to stainless steel, to granite. Just about everything. He said he hasn’t found anything yet that he can’t cut. I saw a 9” thick piece of stainless that was cut.

Yes, those are two horses…pretty neat huh?

Aluminum plates-----------------Kinda muddy--------------------That could’ve been a solid plate

Cutting-------------------------The product (1000 down, 1000 more to go)

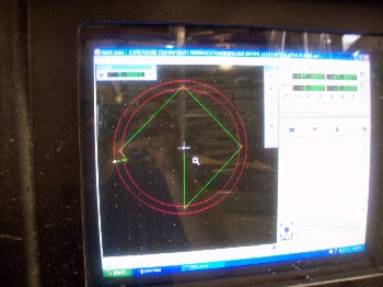

Here’s some doughnuts I made the other night…which is my excuse for missing Safe Team chat. The green lines on the screen indicate where the nozzle will move with out cutting. The red lines indicate where it will cut.

The water jet works by concentrating about 50,000 PSI of water and garnet in to an almost pin point nozzle. Garnet is the cutting abrasive. Without it the water only scratches the surface of the metal.

Garnet

It is textured like fine fine beach sand. He buys it by the 4,400 pound bag full.

Part of a home made I-beam

These are pretty neat gadgets they are.

Jaden

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2008 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.