You don't have to be cooped up in the Bastille like Dr. Manette to mend leather.

*Leather Stitching Awls*

You don't have to be cooped up in the Bastille like Dr. Manette to mend leather.

It has fallen to my lot to be the Rubicon's resident Luddite. If you know your history, Luddism was the reactionary protest movement in the 1800s to the Industrial Revolution and the changes this revolution wrought over previously existing "craft" guilds, trades, and employment more generally. Vast swathes of people were put out of work by cheap factory goods - textiles in the Luddite's case - and this aroused resentment that spilled into sabotage (the word's root refers to workers throwing their "sabots" - their wooden clogs - into the machinery of spinning and weaving engines to destroy them), riots and equally violent repression, to include several hangings. Nowadays, the word "Luddite" simply refers to anyone who obstinately resists modernity. It has lost much of its pejorative nature and nearly all of its political connotation - "Luddite" had a similar "emotional loading" to terms like "anarchist" in the early 1900s, "militant" in the middle of the 20th century, or "terrorist" now. In the 21st century, "Luddite" usually refers to a quaint eccentric or, if a certain affectation is assumed, to the "steampunk" sensibility.

The word applies to me - in my brain anyway - insofar as the things I write about tend to fall technologically between the grub-and-flint of the "Bushcrafter" and the cutting-edge cyberpunk solutions of the site's owner (to whom be the Honor and Glory forever and ever, Peace Be Upon Him etc.). I've written before about the desirability of being able to approach any problem in three ways - High Tech, Low-Tech and No-Tech. With but few exceptions, my solutions fall in the middle - the Low-Tech category.

This is for two reasons. First, I am not expert at High-Tech or No-Tech. High-Tech preparedness is capably covered by the articles here on the Rubicon written by the site's owner (PBUH etc. & so on) and others. If you want an expert for No-Tech, read anything Mors Kochanski wrote, starting with "Bushcraft." If you only read and practiced what this kindly and generous contributor to the common stock of human knowledge had to say, you'd know 90% of everything you needed in order to prevail in the boreal forest; add in a few things for areas he didn't cover - such as deserts, jungles (a jungle is a rainforest you don't want to be in any longer), urban and so forth - and you've covered the remaining ten percent for the rest of the un-watered Earth.

The second and more important reason is that "Low-Tech" is the environment where I'm most comfortable. Take a tour of Chez GVI and you'd discover many things that don't require electricity or internet connectivity. The clocks here are (mostly) wind-up, the coffee and tea here are made without electricity, the library (which like any good library has something to offend everyone, including me!) is mostly "dead-tree" format, much of the mathematics employed in my work or around the house are done without calculators or computers, the sewing is done on a 117-year old treadle machine, and the woodworking tools here are all powered by the oatmeal and coffee I had for breakfast this morning.

I'm no purist - this essay wasn't written on a typewriter, there's a new cell phone within inches of me as I type, the fridge works just fine and I do my paying work via electronic instrument and AutoCAD. But "Low-Tech" appeals to me for more reasons than off-grid preparedness, not least of which are purely aesthetic and subjective.

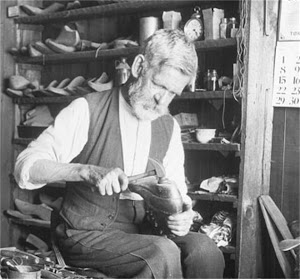

Leatherwork as an industry does not seem to have become automated in the same way car manufacturing or computer-chip making are. There are plenty of machines, of course, and the work is done in factories like everything else, but it's much closer to trades and "guilds" than to robotics and computers. The work by its nature requires skills and degrees of judgment that cannot yet economically be carried out by a machine. I say this to make the case that all the processes in leatherwork scale down to the individual. In other words, everything a boot or purse or coat factory does, at an industrial scale, can be done by an individual, at an individual scale.

You may not wish to make your own boots or shoes. You may not wish to make your own bags or coats or what-have-you. And that's fine. But you may well wish to repair a floppy or worn-out shoe sole, or mend a hole in a bag or a rip in a jacket. Further, you may need to, and there may be no repair shop available - there are few enough now already!

The ability to mend or replace whatever is a self-evident survival skill. The rest of this essay will discuss a Low-Tech enabling technology - the stitching awl - that allows us to do this with leather or heavy textiles. It will not go into leathercraft more generally. The best place to learn, if you know nothing of it and wish to start, is the Boy Scout Merit Badge Booklet on Leathercraft. Resources for children and youth are always the best place to learn anything new. They don't assume the learner knows anything about the topic; they have lots of pictures and glossary terms, and they're written in a friendly, can-do style that encourages learning.

Stitching awls come in three types. The first type is simply a thin piercing instrument with a handle on one end.

A wine cork is an EXTREMELY prudent thing to stick on the other end.

It's for poking holes in leather so as to allow the threaded needle to go through more easily. We will not discuss it further - it's only shown because if you do a search on a site like amazon you will see examples of it because that's what it's called. It's not what we're talking about.

The ones we're keen to learn about might best be referred to as "patent stitching awls," for no better reason than to set them off against their simpler cousin above. They are sometimes called "sewing awls" for this reason but the terms are all interchangeable. I own two; one which I've had for decades, and one which just arrived in today's Big-Blue-Truck delivery. They both do exactly the same thing and in almost exactly the same way, but there are differences between them.

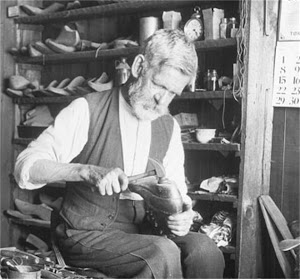

The first one I owned - and the one with which I'm most familiar - goes by the populist-sounding name of "The Awl For ALL." Sounds like the sort of thing Pete Seeger or Eugene V. Debs might advertise if they'd been given to advertising instead of rabble-rousing. It was patented in 1905 and is still made in its original form by the C.A. Myers Co. of Arlington Heights, Illinois.

The one I own

From the manufacturer's website

Fuller instructions and video can be found here

I had occasion to use my stitching awl a few days ago when I needed to make a small "wallet" for a couple of handsaws. They have thin blades and can easily be kinked or dented, or the small teeth be thrown out of set or broken altogether.

The saws in their wallet. It's a piece of pigskin folded into thirds so as to make two pockets.

Flush-cut and dovetail saw. Flush-cut saws are usually only flush on one side, hence the marking.

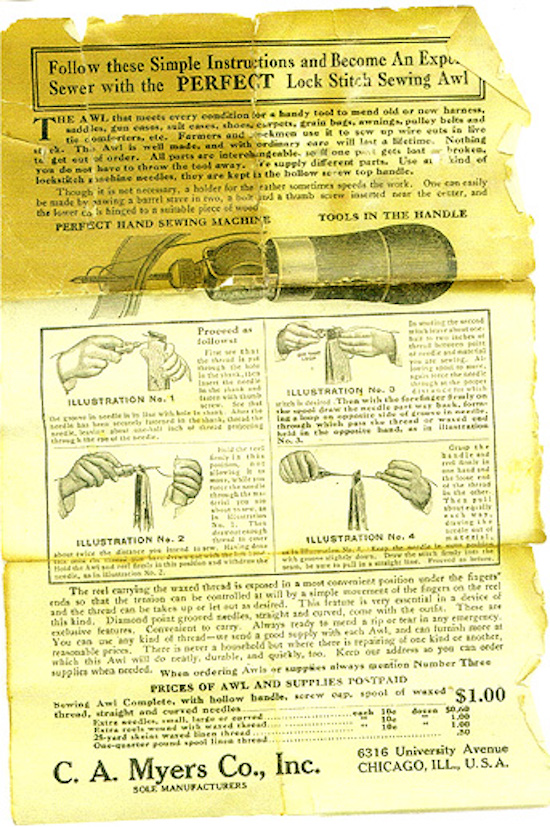

The second one, which arrived today, is an imported ""Speedy Stitcher" which was originally patented in 1909 and is likewise still made in the United States. The original is in fact made in my home state of Indiana - if I'd known this earlier I'd have bought it from them, but I only just found this out while doing the research for this essay. On the other hand, the company says it makes its product for export, so it may well be that mine went from Southern Indiana all the way to China, only to come back here to Northwest Indiana. I'll never know.

This is what arrived today. The several spools of waxed thread was a nice bonus.

Photo from U.S. Manufacturer. Instructions can be found here

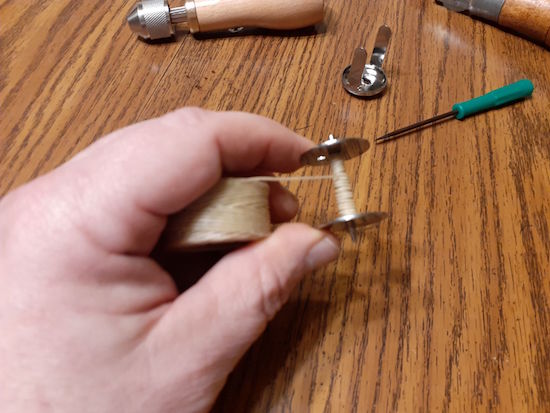

You will see that they both do essentially the same thing - hold a sewing/piercing needle and spool of thread in the same place, allowing you to make a lockstitch according to the instructions for each. Note, however, that they do this in slightly different ways. The "Awl for ALL" holds a small spool just behind the needle, while the "Speedy Stitcher" holds it in a spool (a bobbin, really) in the back of the handle. They both require the user to draw out the length of thread for the "back" side of the lock stitch at the very beginning, and they both require the user to thread this "running end" by hand through a loop of thread created by withdrawing the needle slightly after having pierced the second hole. They both take practice to learn to use correctly, because this is a very "manual" skill in addition to a "mental" one.

Both companies advertise that their products make a lockstitch "just like a sewing machine." The lockstitch is the part that's "just like a sewing machine" - sewing machines make the same stitch but in a different way. Knowledge of how sewing machines work isn't mandatory; but from my own experience I can say that I understand both devices much better after figuring out my old Singer treadle machine than I did before it came into my possession.

Stitching awls make much more sense if you know how these things work but it isn't necessary

Prior to the arrival of the "Speedy Stitcher," I had always thought the little nickel-plated button on its handle slid up-and-down the track in front of it. But I had no idea why it did that. Now that it's arrived, I find that this button does not move at all. It serves a function very similar to the tension-regulating parts of a sewing machine.

The button on the Speedy Stitcher performs the same function as all of this stuff on my sewing machine - keeping the thread at the proper tension so it stays put and doesn't get tangled up.

Winding the thread on the spool/bobbin is tedious with both. You can put a LOT more thread on the spool/bobbin of the Speedy Stitcher, but this must be set against the possibility that you might wish to change the color or thickness of thread you use, and it's an even bigger pain in the butt to unspool this stuff - and find somewhere to put it - than it is to fill the spool in the first place. If you only use one color and thickness of thread (white linen is most common for leatherwork and will hold EVERYTHING), this isn't a problem.

I only put a bit on the bobbin for the test that follows

In the interest of fairness, I just now set both these devices up and made a short series of lockstitches with each on a scrap of leather. I took the liberty of soaking the scrap and pre-punching the holes because

What I mean by this is that I didn't set these things up like some Bear Grylls test where I'm cold, wet, hungry and miserable, and have to repair my tent in the forest when it's a rainy 39degF and I'm being chased by the Legions-Of-Doom or S.P.E.C.T.R.E. or someone. I'll happily take the lazy way out if it still gives each device a fair hearing.

Yes, those are tiny scissors.

No, Chuck Norris doesn't need candy-pants sissy-priss little scissors.

I'm not Chuck Norris.

Neither are you - get some small scissors.

I set the scrap up in a "stitching pony" which is nothing more than a wooden vise for holding leatherwork while you stitch (see "laziness" above) and did ten lockstitches with each device.

This is the key to making the lockstitch with these things.

Put the awl through as far as it will go, then back up a touch and this loop gets created…

Put the "running end" of the thread through the loop and pull both ends tight such that the "lock" part is hidden between the two pieces of leather.

The result of the two devices is shown below:

Not a dime's worth of difference

Allowing for the difference in the thickness of the two threads - the light-colored stuff is a bit thicker than the black stuff - the two stitching awls were equally easy to use and made stitches of identical quality. The principal difference is that the "Awl For ALL" has no built-in way to regulate tension in the thread. You must do this with your thumb or re-wind the excess stuff every so often. It's a minor inconvenience but one that's hardly worth trifling over. Conversely, the "Speedy Stitcher" runs well, but I discovered that the tension button creates TOO MUCH tension in the thick waxed thread I used. I ended up disengaging the thread from the tension button and pretty much used it in the same manner as the "Awl For ALL," with the problem that I can't re-wind the spool because it's concealed in the handle. In other words - choose your problem.

The "Awl For ALL" is slightly more self-contained, in that the little wrench/screwdriver stows in the handle. The "Speedy Stitcher" came with a dinky screwdriver which cannot stow in the handle and which is necessary to pry open the back to access the spool/bobbin. But if you have a screwdriver on your multitool or pocket knife (you DO have one of those on you at all times, right? RIGHT?!), then this problem ceases to exist. Again - choose your problem.

So which do I recommend? I don't. Get one or the other - there's less difference between these two tools than there is between Coke and Pepsi. You will be happy with either. But DO get one or the other. They are both worth the cost and both will last the rest of your life.

This is a pdf of the Speedy Stitcher Instruction sheet. The pictures are clearer than the ones I've taken.

gvi

www.alpharubicon.com

All materials at this site not otherwise credited are Copyright © 1996 - 2023 Trip Williams. All rights reserved. May be reproduced for personal use only. Use of any material contained herein is subject to stated terms or written permission.